From green electricity to hydrogen - the starting point for climate-neutral energy

At the Bad Lauchstädt Energy Park, everything revolves around green hydrogen. In contrast to the climate-detrimental processes for hydrogen production that are still common today, green hydrogen is produced without any CO2 emissions and is therefore considered a key to a successful energy transition. Only renewable energies are used in electrolysis, a process with which hydrogen is produced. At the Bad Lauchstädt Energy Park, the electricity comes directly from a nearby wind farm. This direct coupling of an electrolysis plant with an on-site wind farm is a world first.

Green electricity from wind for a climate-friendly future

A lot of electricity is needed to produce hydrogen in the electrolysis plant, called an electrolyser. Climate-neutral green hydrogen can only be produced if the required electricity is generated by renewable sources. To ensure this, eight new, state-of-the-art wind turbines will produce renewable electricity for the generation of green hydrogen in the immediate vicinity of the Bad Lauchstädt Energy Park.

The wind turbines with a total rated output of 50 MW can generate up to 145 million kWh of green electricity per year and have a hub height of 169 metres (five turbines), 166 metres (one turbine) and 119.9 metres (two turbines). The latest generation of wind turbines are equipped with ice detection sensors and an additional control system that permanently monitors the turbines and shuts them down if unusual operating conditions are detected.

The wind farm will be built in the immediate vicinity of the A 38/A 143 motorway junction. Three wind turbines will be erected to the east of the A 143 motorway and the remaining five to the west. For regulatory reasons, Bad Lauchstädt Energy Park is not able to utilise the existing wind farm (B). The construction of a new additional wind farm is also absolutely necessary in order to continue generating sufficient electricity for the public supply.

The consortium partner Terrawatt Planungsgesellschaft mbH is responsible for the construction and operation of the wind farm. The company has been developing and implementing wind power and photovoltaic projects for over 25 years and can draw on a wealth of experience from over 300 projects with more than 1,500 wind turbines. Terrawatt ensures the safe operation of the systems through regular inspections and maintenance.

After the approval procedure in accordance with the Federal Immission Control Act (BImSchG) was successfully completed, construction of the wind farm began in April 2023. The first wind turbines are scheduled to be commissioned in the first quarter of 2024.

CONTACT PERSON

Falk Zeuner

Managing Director

Terrawatt Planungsgesellschaft GmbH

Large-scale electrolysis turns wind power into green hydrogen

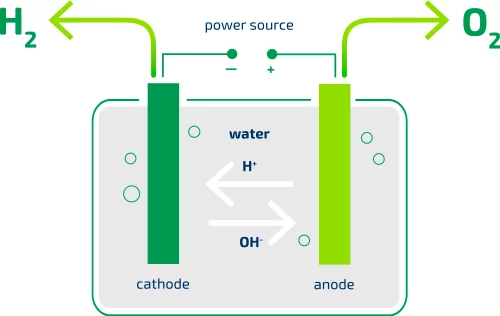

The electrolysis process, in which water is separated into water and oxygen by electricity, was discovered back in 1800. An electric direct current is passed through the water via two electrodes. As a result, oxygen is formed at the positively charged anode and hydrogen at the negatively charged cathode. The hydrogen thus produced is stored, while the oxygen can be safely released into the atmosphere. As the electrolyser used in the Bad Lauchstädt Energy Park produces very large amounts of energy with an output of 30 megawatts (MW), this is also referred to as large-scale electrolysis. The manufacturer of this large-scale electrolysis plant is Sunfire, based in Dresden. The electrolysis plant will be built on a site measuring 80 x 130 metres and will produce around 26.9 million m3 of hydrogen per year.

The direct coupling of wind power from the nearby wind farm with a large-scale electrolysis plant of up to 30 MW is a world first. Both components are directly electrically connected via an area network. This means that this network does not belong to any network operator, but is operated privately.

The consortium partners Uniper and VNG Handel & Vertrieb GmbH are responsible for the construction and operation of the large-scale electrolysis plant via a joint venture named Elektrolyse Mitteldeutschland GmbH (EMG). As an international energy company and pioneer in the field of hydrogen, Uniper is implementing projects worldwide along the entire hydrogen value chain in order to make it usable as a mainstay of the energy supply. VNG Handel & Vertrieb GmbH, with its expertise in wholesale gas trading, is responsible for marketing the hydrogen produced at the Bad Lauchstädt Energy Park. With sales offices throughout Germany and in neighbouring countries and business contacts in many parts of Europe, it is supporting the roll-out of the European hydrogen economy. The construction of the large-scale electrolyser began with the ceremonial first ground-breaking ceremony in June 2023. Construction will take around two years.

Safe production of green hydrogen

In terms of safety, hydrogen itself is comparable to conventional gases such as biomethane or natural gas. By adhering to strict safety precautions, safe operation can be guaranteed at all times. The safety precautions include the use of sensors in the electrolysis systems that reliably detect any hydrogen leakage so that defects can be rectified quickly. Before the systems in the Bad Lauchstädt Energy Park go into operation, they undergo strict safety tests and are inspected by the technical inspection agency (“TÜV”).

CONTACT PERSON

Xenia Papst

Senior Commercial Manager - Hydrogen Germany

UNIPER Hydrogen GmbH